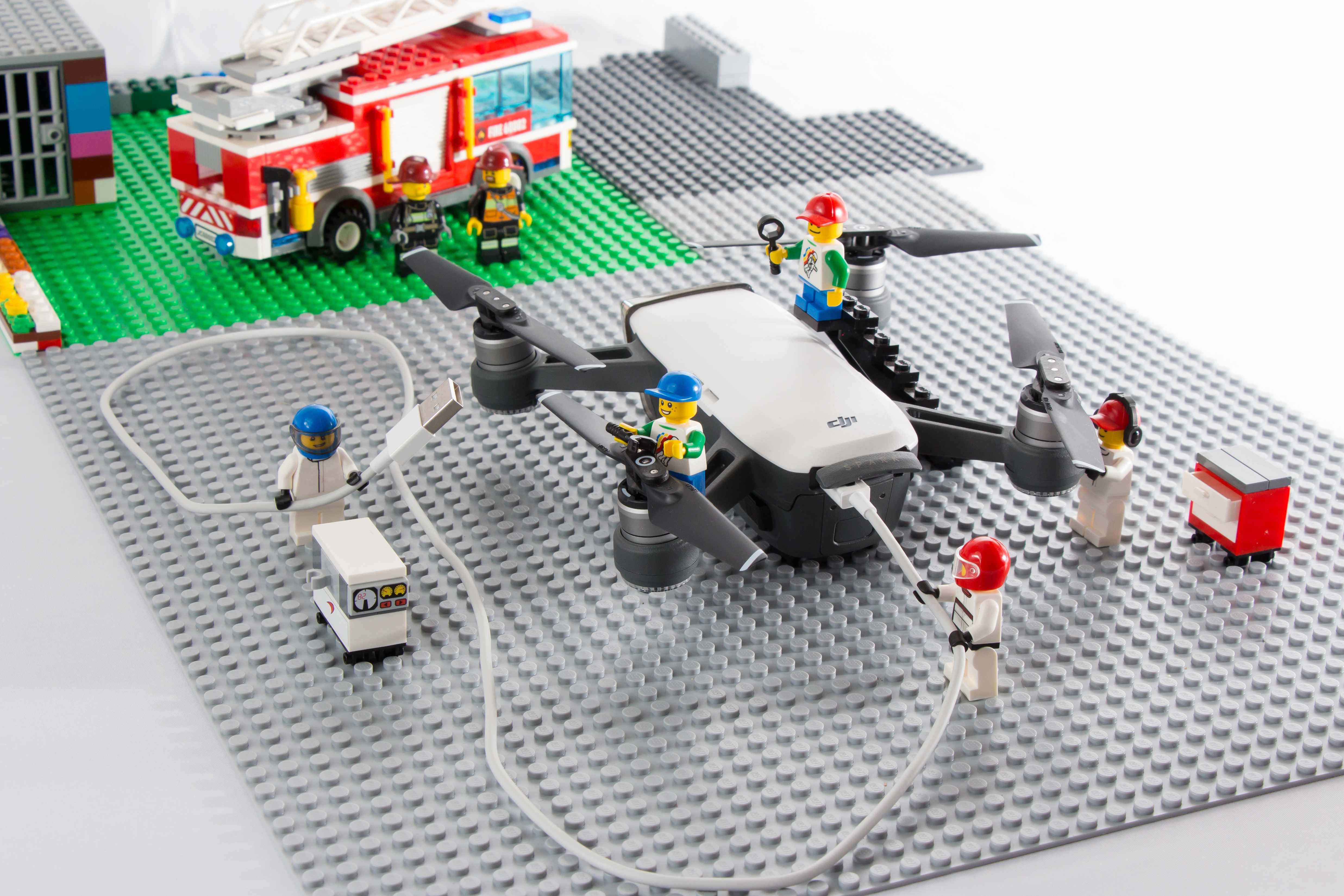

I loved playing with LEGOs when I was a child. The ability to take random pieces and repeatedly connect them together into something different always sparked my imagination. At one point, I had filled up a significant portion of the living room with a giant LEGO city. Little did I know, the same ideas would be applied to electronics and software development, allowing individual pieces to be connected and reconnected in specific ways into new, innovative products.

A modular circuit design approach is an excellent way to create new electronics from independent parts. These independent parts must be connectable with standardized interfaces that can easily be stacked, rearranged, customized, and reused in other systems. Modularity can be implemented at the hardware development stage and in the software framework, where a software application is broken down into separate, distinct parts. So who benefits from taking a modular circuit design approach instead of building PCBs from scratch? Let’s take a closer look at these ideas.

Get to Market Faster with Modular Circuit Design

In the embedded industry, modules are created to cater to specific functions that might be required in a broad range of products. Examples include modules for power management, communication, data acquisition, display, processing, and many more. Modular design methodologies, in most cases, proceed within an agile development methodology compared to the typical waterfall framework.

If this sounds like PCB design reuse, then you’re on the right track: the two ideas are similar. The difference is that reusing functional blocks from a previous PCB project requires manually designing the connection between blocks each time a new product is created. In addition, the older blocks must be originally designed to be modular, i.e., multiple blocks must be designed such that they already provide the necessary standardized connections between blocks.

Two major challenges one sees when embarking on a hardware development project are time and cost. Typically, time and costs in a project are allotted to engineering and development. Engineers and developers embarking on a new project tend to spend their time developing the electronics and circuitry from scratch. This requires significant time and may proceed over several iterations, and it requires a team with the required skills and experience.

time and costs in a project are allotted to engineering and development

Taking a modular circuit design and engineering approach requires working with standardized modules that have well-defined connections between them. If you have access to these modules and a design tool to define the connections between them, you can focus on designing the functionality and form factor required for your next product, rather than taking time to engineer connections between disparate functional blocks in a new product.

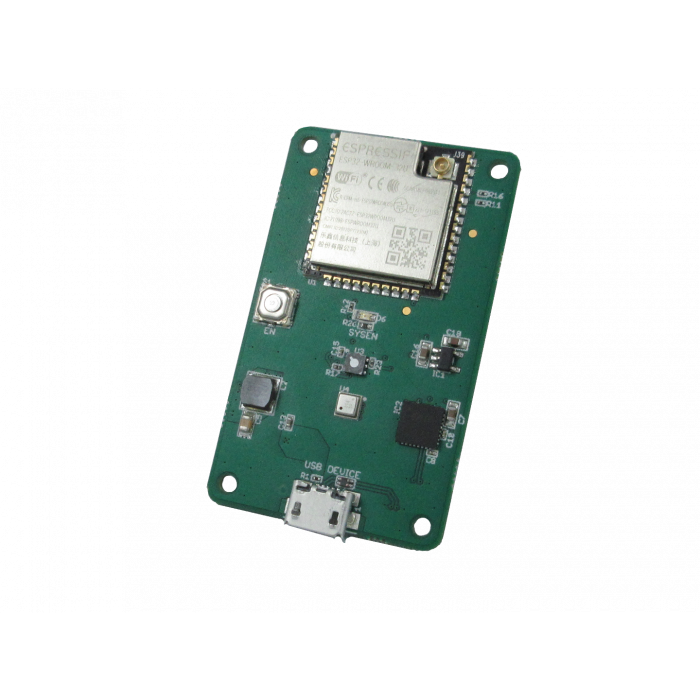

Modular circuit design allows you to save on engineering development time and costs by using proven hardware modules that can easily integrate into your design while still allowing you to build a custom product. Some examples include the ESP32 Air Quality Sensor Board, Raspberry Pi Compute Module, or an AI accelerator module that easily plugs into any existing hardware platform.

Who Benefits from Modular Circuit Design?

Hardware Engineers & Developers

One group that benefits from a modular design approach is the engineers and hardware developers building a custom product. Engineers can focus on functionality and embedded software for their system rather than constantly reinventing the wheel. This helps a product design team bring a new product to market faster.

Embedded Software Developers

Embedded developers also greatly benefit from a modular design approach. Software engineers can easily focus on building software applications for each module and run independent unit tests before the full system is available. Embedded developers don’t need to focus on low-level development tasks as IDEs for different modules already exist. This also allows embedded engineers to speed up the development cycle and leverage resources from the open-source community as needed

End Users and Clients

In some cases, a client may request a feature be included in the end product, but after beta testing a prototype, decide that they want a different feature in the same product. This could incur an extensive redesign in a customized embedded system, but taking a modular design approach allows designers to easily exchange functionality by swapping modules. This ensures products and systems are built with scalability in mind while being future-proofed against changes in client requirements.

Entrepreneurs and Startups

Entrepreneurs and Startups

Not all entrepreneurs are professional electronics engineers. They may have some idea of the hardware capabilities they need in their new product, but they may not have the PCB design expertise to build it from scratch. Rather than building a custom board, a new company can quickly create a powerful Version 1.0 of their new product with much lower cost than building from scratch. These initial product releases created with modular circuit design tools are superior to anything created with a typical microcontroller board or development board.

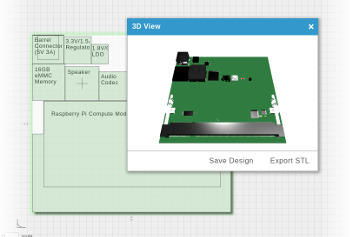

Start Your Modular Circuit Design Journey with Geppetto

Kickstarting your custom product with modular circuit design tools is not rocket science. Geppetto’s online platform allows you to design your customized board from a broad range of fully functional COMs and other hardware modules. All these tools are available in a browser-based design interface that allows you to create fully functional modular hardware systems and quickly plan for production. It’s free to get started and experiment with any design you can imagine.

Take a look at some Gumstix customer success stories or contact us today to learn more about our products, design tools, and services.

RSS

RSS