Energy efficient embedded computer developed in Geppetto D20 reduces cost and improves path to remote diagnostic care.

For medical researchers and developers designing tomorrow’s wearable health sensors and instruments, off-the-self form-factor boards more often complicate product design process rather than simplify it. The size and shape of market ready boards, for example, cannot be easily altered. Moreover, the mass production of a medical device built around boards with unneeded connectors and features add unnecessary costs to already tight product budgets.

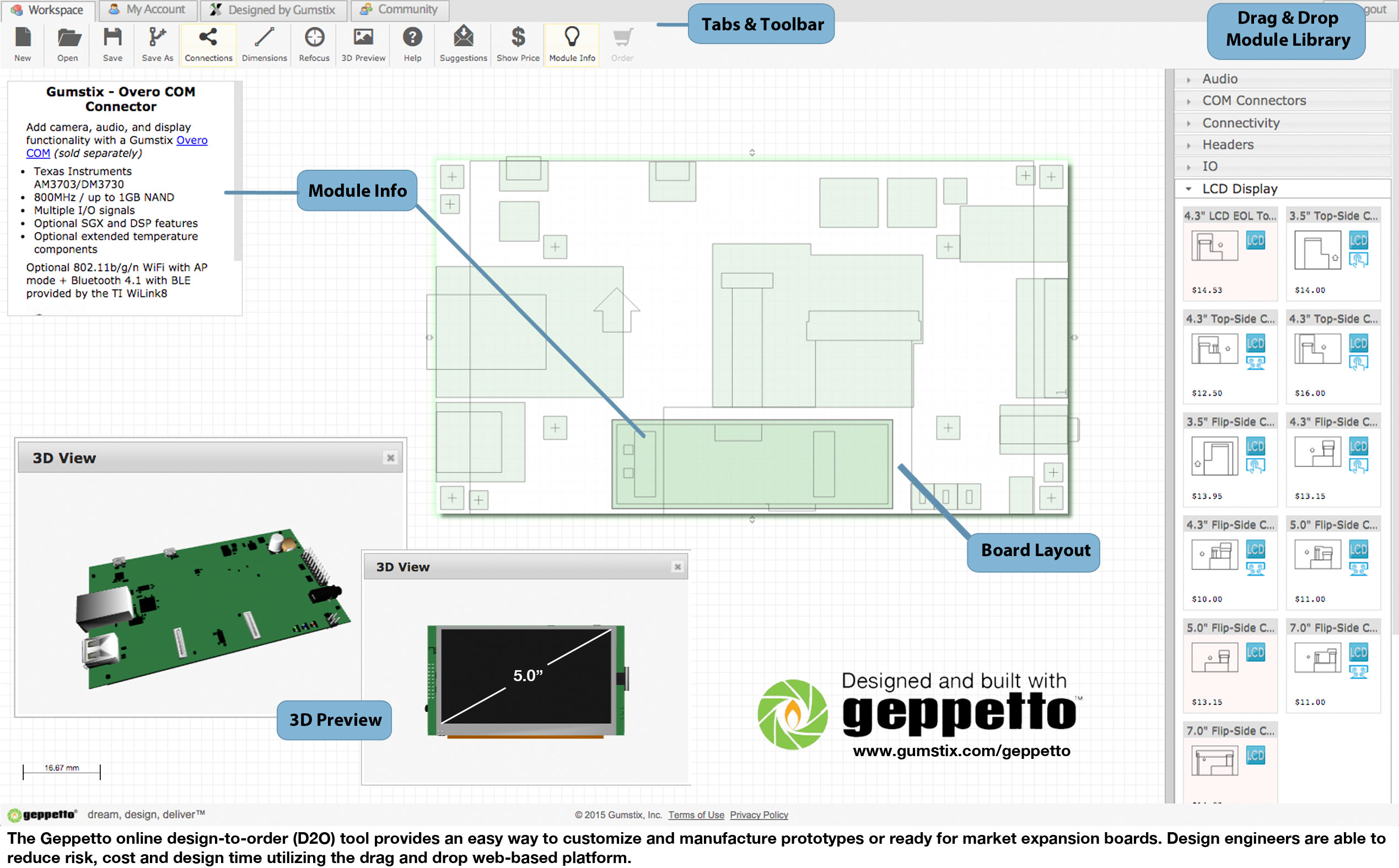

Gumstix’s Geppetto D20, a design-to-order web-based platform for designing and customizing form-factor boards, helps to address these problems by allowing researchers and developers to simplify and accelerate their product development. By deciding whether to either modify a pre-existing design template or create their own boards from scratch, developers can meet their project deadlines in a timely manner. With Geppetto D20, you need only pay only for what the project requires and Gumstix engineers will then manufacture and ship the boards in 15 days.

Drag and Drop Design Interface simplifies and reduces cost and time to market.

The Abstats System, developed by by a team of medical researchers at UCLA’s Wireless Health Institute (WHI) and distributed and licensed by GI Logic, is a recent example of medical researchers utilizing the flexibility of Geppetto D20. A wearable, acoustic sensor, the Abstats System is used to diagnose and detect gastrointestinal disorders in patients, whether they are under ambulatory care or are in their own homes. The WHI team used Geppetto to rapidly design a small and energy efficient expansion board with a connector for a LCD monitor. Integrating their board design with Gumstix’s Linux-based Overo Earth computer-on-module (600-MHz ARM Cortex-A8 processor; 512MB RAM; 512 MB NAND flash memory), not only are the embedded components of the Abstats System optimally designed for wearable medical devices but they provide the computational power to handle the medical software written by the WHI team to handle large amounts of digitized medical information. (read full article)

RSS

RSS