A report from the McKinsey Global Institute estimates that IoT devices could have an annual economic impact of $3.9 trillion to $11.1 trillion across many different settings by 2025, including factories, cities, retail environments, and the human body. IoT devices can be used to gather and process information remotely, either for automation or analysis purposes.

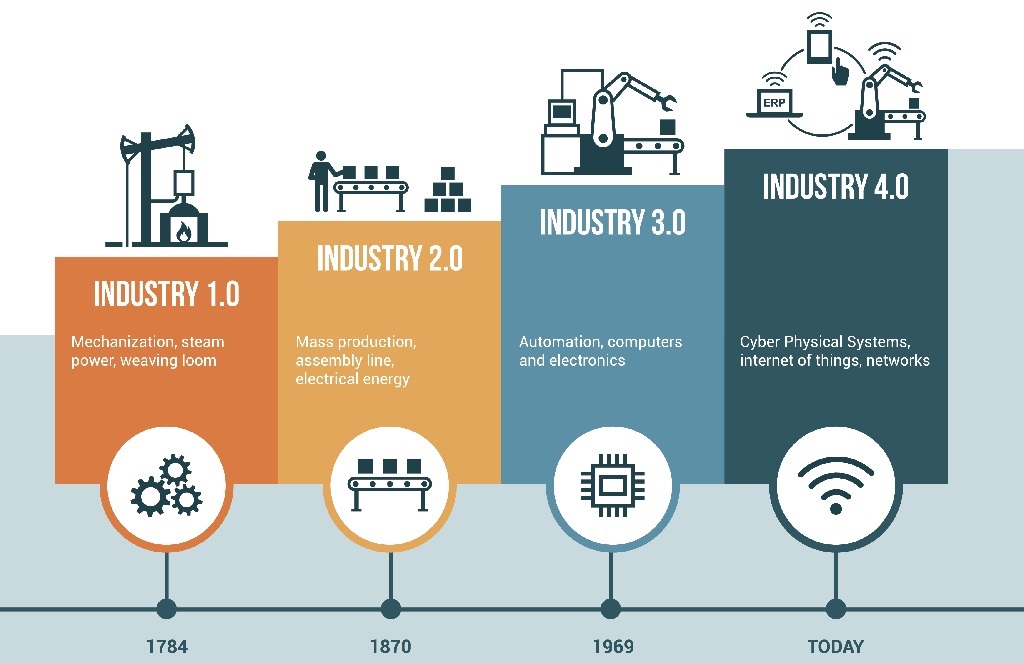

IoT devices can be deployed in virtually every sector, but one most promising use will be in environmental monitoring and monitoring of factory assets. The term industrial internet of things (coined IIoT) was defined to refer to connected systems that can be used to remotely monitor and control industrial processes as part of Industry 4.0.

Predictive maintenance and asset tracking are two significant benefits of IIoT in industrial settings as equipment failure could create safety hazards and incur unnecessary costs. Environmental monitoring adds an aspect of safety for factory workers in industrial settings. No matter the application, any device for remote monitoring will require an IoT protocol to support wireless connectivity.

IoT Protocols For Environmental Monitoring

IoT environmental sensors can be deployed in the most inhuman locations, allowing data to be collected without the need for regular visits by humans. These sensors can be accessed over the internet or over other wireless IoT protocols, ideally miles away from the target location.

One of the challenges in deploying IoT sensors for environmental monitoring is the lack of internet connectivity in most places

One of the challenges in deploying IoT sensors for environmental monitoring is the lack of internet connectivity in most places, or the exorbitant cost of providing internet infrastructure in those places. For example, in wildfire monitoring in the rainforest, the chances of having internet connectivity are nearly zero unless you are relying on satellite connectivity, which also adds the question of power and costs.

IoT-based environment monitoring needs to be designed with sustainability at its core. This means it should be easily accessible, support long-distance communication, consume low power, have long usable life span, be durable, and be cost-effective. Firmware updates should also be easy to apply over the air if possible as firmware updates are essential for large scale deployment of connected devices. One IoT protocol that fits these requirements is low-power, wide-area network (LPWAN).LPWAN is often regarded as the most well-suited to environmental monitoring. Sensors that use LPWAN can stay in a location for long periods and send data over long distances. LPWAN is also energy efficient and scalable; a battery on an LPWAN based remote device could potentially last up to 10 years without the need for a recharge. The low throughput is ideal for many industrial applications. Three prominent LPWAN protocols are

- LoRa (LoRaWAN)

- SigFox

- Weightless

Each of these technologies offers its benefits, although comparing each of these is beyond the scope of this post. EDN released an excellent whitepaper that compares each of these protocols. Note page 4 in this PDF in particular, which includes a table with frequency bands, channel width, range, transmit power, packet sizes (minimal or maximal), downlink and uplink data rates, maximum number of connected devices, topology, roaming capability, and status for these protocols.

As it currently stands, LoRaWAN seems to be among the ideal IoT protocols for LPWAN, mostly due to its open nature. Not to confuse LoRaWAN with LoRa – LoRaWAN is the communication protocol and system architecture for the network while LoRa is the physical radio layer enabling the long-range communication link. The highest recorded distance ever recorded for LoRaWAN is 766 km, a formidable distance that shows the power of LPWAN technology.

Building an IoT Protocol Into Your System with Geppetto

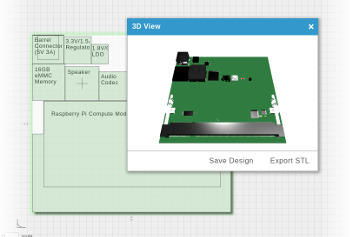

The modular hardware design tools in Geppetto allow engineers and potential entrepreneurs to bring their hardware product to life with little or no experience. These online design tools include standard COMs and other important modules that you can easily use to construct a fully-functional board in an online platform. You can then order a production-ready board within a few days.

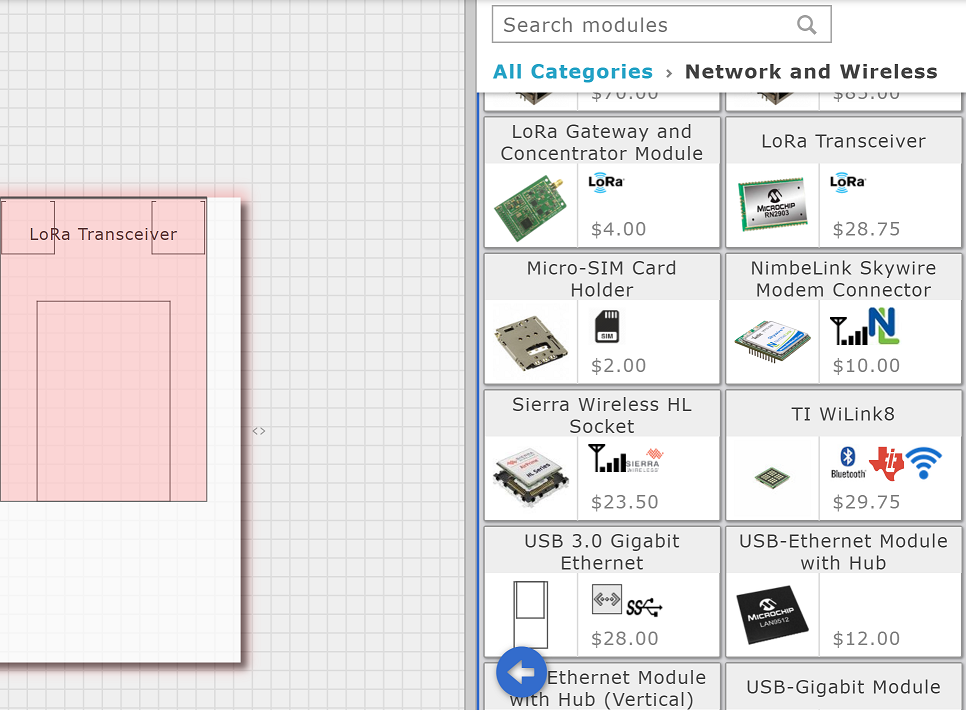

Geppetto comes preloaded with ready-made LPWAN solutions to support your development. On the Geppetto builder environment, you can easily add a LoRa concentrator module if you are interested in building a LoRa Gateway device, or can add s LoRa transceiver to your board without worrying about the finer points of PCB design. The connections between COMs and other modules are predefined in Geppetto, which greatly cuts down your design time.

Although LoRa is the current officially-supported LPWAN technology on Geppetto, you can still include other LPWAN technologies by making use of headers or external ports. Aside from LPWAN technologies, there are also other IoT technologies that you can include in your project like Zigbee, WiFi, Bluetooth, and Ethernet.

The modular hardware design tools in Geppetto allow any engineer to streamline the design and production process for IoT devices and networks. You’ll have access to plenty of components and COMs to support various IoT protocols when you work with Geppetto, and you can quickly create fully functional modular hardware systems in a browser-based design interface. Your designs will also be production ready and adaptable for nearly any application.

Take a look at some Gumstix customer success stories or Contact us today to learn more about our products, design tools, and services.

RSS

RSS